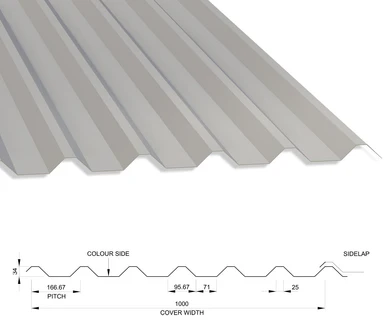

34/1000 box profile 0.5 thick galvanised roofing sheets are one of our most popular sheets, with each single skin sheet having 7 strong 166mm profiles across its width. With a profile height of 34mm and coverage of 1000mm when installed, these 34/1000 box profile sheets give you a simple yet... Read more

32/1000 Box Profile 0.7 Thick Galvanised Roof Sheets 1000mm Width

34/1000 box profile 0.5 thick galvanised roofing sheets are one of our most popular sheets, with each single skin sheet having 7 strong 166mm profiles across its width. With a profile height of 34mm and coverage of 1000mm when installed, these 34/1000 box profile sheets give you a simple yet strong way to cover your build. Each 34/1000 box profile sheet will give your roof a secure weatherproof lap from sheet to sheet.

- Cover Width: 1000mm when lapped

- Profile Height: 32mm

- Pitch: 200mm

- Sheet Thickness: 0.5mm or 0.7mm

- Minimum Roof Pitch: 4 Degrees

- Max Sheet Length: 8m in 0.5mm thickness and upto 10m in 0.7mm thickness

- Colours: Galvanised

Imposed Load (+ve)

Narrow Flange in Compression (Single Span)

Deflection Limit L/200 *

|

FACTORED IMPOSED LOADS (kN/m2) (positive +ve) |

|||||||||||||||||

|

Thickness (mm) |

Weight (kg/m2) |

Span Condition |

Span (m) |

||||||||||||||

|

1.00 |

1.10 |

1.20 |

1.30 |

1.40 |

1.50 |

1.60 |

1.70 |

1.80 |

1.90 |

2.00 |

2.10 |

2.20 |

2.30 |

2.40 |

|||

|

0.50 |

4.90 |

Single |

3.47 |

2.85 |

2.38 |

2.02 |

1.73 |

1.50 |

1.23 |

1.02 |

0.86 |

0.72 |

0.62 |

0.53 |

- |

- |

- |

|

Double |

2.27 |

1.96 |

1.71 |

1.50 |

1.34 |

1.19 |

1.07 |

0.97 |

0.88 |

0.81 |

0.74 |

0.68 |

0.63 |

0.58 |

0.54 |

||

|

Multi |

2.70 |

2.33 |

2.04 |

1.80 |

1.60 |

1.43 |

1.29 |

1.17 |

1.07 |

0.98 |

0.90 |

0.83 |

0.76 |

0.67 |

0.59 |

||

|

0.70 |

6.41 |

Single |

6.00 |

4.92 |

4.11 |

3.48 |

2.82 |

2.28 |

1.87 |

1.55 |

1.30 |

1.10 |

0.94 |

0.81 |

0.71 |

0.62 |

0.54 |

|

Double |

3.83 |

3.29 |

2.86 |

2.51 |

2.22 |

1.98 |

1.77 |

1.60 |

1.45 |

1.32 |

1.21 |

1.11 |

1.03 |

0.95 |

0.88 |

||

|

Multi |

4.57 |

3.94 |

3.43 |

3.02 |

2.67 |

2.39 |

2.14 |

1.94 |

1.76 |

1.61 |

1.47 |

1.35 |

1.18 |

1.03 |

0.90 |

||

Wind Suction Load (-ve)

Broad Flange in Compression (Single Span)

Deflection Limit L/150 *

|

FACTORED IMPOSED LOADS (kN/m2) (positive +ve) |

|||||||||||||||||

|

Thickness (mm) |

Weight (kg/m2) |

Span Condition |

Span (m) |

||||||||||||||

|

1.00 |

1.10 |

1.20 |

1.30 |

1.40 |

1.50 |

1.60 |

1.70 |

1.80 |

1.90 |

2.00 |

2.10 |

2.20 |

2.30 |

2.40 |

|||

|

0.50 |

4.90 |

Single |

3.90 |

3.22 |

2.71 |

2.31 |

1.99 |

1.73 |

1.52 |

1.27 |

1.07 |

0.91 |

0.78 |

0.68 |

0.59 |

0.51 |

- |

|

Double |

3.67 |

3.04 |

2.55 |

2.17 |

1.87 |

1.63 |

1.44 |

1.27 |

1.13 |

1.02 |

0.92 |

0.83 |

0.76 |

0.69 |

0.64 |

||

|

Multi |

4.59 |

3.80 |

3.19 |

2.72 |

2.34 |

2.04 |

1.79 |

1.59 |

1.42 |

1.27 |

1.15 |

1.04 |

0.95 |

0.86 |

0.75 |

||

|

0.70 |

6.41 |

Single |

6.02 |

4.98 |

4.18 |

3.56 |

3.07 |

2.68 |

2.32 |

1.93 |

1.63 |

1.39 |

1.19 |

1.03 |

0.89 |

0.78 |

0.69 |

|

Double |

6.34 |

5.24 |

4.40 |

3.75 |

3.24 |

2.82 |

2.48 |

2.19 |

1.96 |

1.76 |

1.59 |

1.44 |

1.31 |

1.20 |

1.10 |

||

|

Multi |

7.93 |

6.55 |

5.51 |

4.69 |

4.05 |

3.52 |

3.10 |

2.74 |

2.45 |

2.20 |

1.98 |

1.71 |

1.49 |

1.30 |

1.15 |

||

Notes:

- This table has been produced for roof cladding applications. However, it can be safely used for wall cladding.

- Safe Imposed loads factored by 1.6 Wind suction loads factored by 1.4

- Deflection limit applied to imposed loads –L/200

- Deflection limit applied to suction loads –L/150

CCP recommend the use of 0.7mm thick material for roof cladding

Click here for all of our Anti-con products

Anti-Con is an effective solution to combat the effects of water condensation on the underside of your roof cladding. Colour Clad apply the Anti-Con (DR!PSTOP) lining during the manufacturing process, its rolled simultaneously with the steel through or profiling mill and applied to the reverse of the roofing sheet.

DR!PSTOP is perfect for single skin applications to ensure any humidity in the air evaporates and is absorbed in locations where it is important that the condensation is under control, Anti-Con is ideal for;

- Chill Rooms

- Work Shops

- Equestrian and Agricultural Buildings

- Garden Sheds/Summer Houses

- Garages

- Grain Stores

As previously mentioned we apply the Anti-Con lining during the roll forming stage, when rolling the roofing sheets we allow the overlap edge to be free of Anti-Con, this in turn will minimise the risk of water being drawn into the lap through symphonic action.

How It Works

Colour Clad Profiles DR!PSTOP solution helps to control condensation in environments where it occurs often. For Anti-Con to work effectively the building has to be adequately ventilated to allow the Anti-Con fleece to dry out between cycles. Ideally the ridge and eaves should be left open without the use of foam fillers, if the use of foam fillers is a requirement then an alternative roof construction should be considered. The roof pitch also has a significant bearing on the products performance and a minimum roof pitch of 10° is recommended, for roof pitches below 10° please seek advice from our sales team.

When Colour Clad Profiles Anti-Con is used in a livestock situation the humidity generated by these animals can be quite high, the table below shows the moisture levels produced by livestock and the area required by each animal to keep humidity levels under 80gm/m²/hour.

Animal | Weight | Moisture Produced | Area Requirement Per Animal |

Cows | 500kg | 361gm/hour | 4.51m² |

Horses | 500kg | 361gm/hour | 4.51m² |

Sheep | 100kg | 83gm/hour | 1.04m² |

Pigs | 100kg | 83gm/hour | 1.04m² |

Chickens | 2.2kg | 5.5gm/hour | 0.07m² |

Storage of your Anti-Con Sheets

Anti-Con lined roofing sheets should be stored (where possible) indoors prior to installation, where this is not possible the packs of material must be stored off the ground and kept dry. Profiled sheets should not be allowed to slide on each other or onto steelwork as this will minimise the chance of the fleece becoming damaged and snagging. If the backing coat becomes dirty it can be cleaned using a pressure washer if possible, in the case of livestock buildings this should be done once a year with a solution containing fungicide.

Related products

-

Sale

from £12.00Colour Clad Profiles Ltdfrom £12.00 /m INC VAT

Sale

from £12.00Colour Clad Profiles Ltdfrom £12.00 /m INC VATGalvanised Corrugated Roofing Sheets 0.7 Thick 13/3

Colour Clad Profiles 13/3 Single Skin 0.7mm Galvanised Corrugated Roofing Sheets deliver an effective solution for your roofing requirements. Colo...

View full details -

Sale

from £12.00Colour Clad Profiles Ltdfrom £12.00 INC VAT

Sale

from £12.00Colour Clad Profiles Ltdfrom £12.00 INC VAT34/1000 Box Profile 0.7 Thick Galvanised Roof Sheet 1000mm Width

34/1000 box profile 0.5 thick galvanised roofing sheets are one of our most popular sheets, with each single skin sheet having 7 strong 166mm prof...

View full details -

Sale

from £13.14Colour Clad Profiles LtdOriginal Price £16.62from £13.14 /m INC VAT

Sale

from £13.14Colour Clad Profiles LtdOriginal Price £16.62from £13.14 /m INC VAT32/1000 Box Profile 0.7 Thick Polyester Paint Coated Roof Sheet Goosewing Grey (10A05) 1000mm Width

Colour Clad Profiles 32/1000 Single Skin 0.7mm Polyester (paint finish) Box Profile Sheets deliver an effective solution for your roofing require...

View full details -

Sale

from £13.14Colour Clad Profiles LtdOriginal Price £16.65from £13.14 /m INC VAT

Sale

from £13.14Colour Clad Profiles LtdOriginal Price £16.65from £13.14 /m INC VAT34/1000 Box Profile 0.7 Polyester Paint Coated Roof Sheet Goosewing Grey (10A05) 1000mm Width

Colour Clad Profiles 34/1000 Single Skin 0.7mm Polyester (paint finish) Box Profile Sheets deliver an effective solution for your roofing requir...

View full details -

Sale

from £13.14Colour Clad Profiles LtdOriginal Price £16.65from £13.14 /m INC VAT

Sale

from £13.14Colour Clad Profiles LtdOriginal Price £16.65from £13.14 /m INC VAT13/3 Corrugated 0.7 Thick Polyester Paint Coated Roof Sheet Goosewing Grey (10A05) 1000mm Width

13/3 Corrugated Roofing Sheets – 0.7mm Polyester-Coated Steel Robust, Lightweight & Cost-Effective Roofing for Trade and DIY Projects Our 13...

View full details